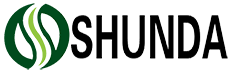

We supply complete EPS foam production line and turnkey project. We can upgrade the machines according to customers’ requirements. Our company floor area 18000 square meters, has four big modern workshops.

Ⅰ.MAIN FEATURES:

1.Performing fully automatic, semi-automatic, middle starting and manual operating mode;

2.Using hydraulic system mold clamping, stable and reliable;

3.The main intake of steam control valve is pneumatic valve, good sealing, and long life;

4.Using the programmable control with color touch screen control, easy to operate;

5.Automatic feeding, convenience and high efficiency;

6.The main components (CPU template, touch screen, etc.) all use international and domestic brands;

7.Forced air-cooled refrigeration, high cooling efficiency, low moisture content;

8.Special aluminum alloy plate used in the mold has good intensity, durability and thermal conductivity.

Ⅱ.Technical parameters:

Block polystyrene machine processors are facing two critical dilemmas which are high quality and effective energy saving. We can offer our customer the optimal & economical efficiency. Our new series block moulding machine can guarantee our customer the minimum investment cost at fastest return. Our customer can have the highest competitiveness in the market, thanks to our innovative design which is specially in short cycle time, good fusion and even density distribution.

| Description | Unit | PSB-2000 | PSB-3000 | PSB-4000 | PSB-6000 | |

| Mould Cavity Size(mm) | L*W*H | 2040*1240*630 | 3060*1240*630 | 4080*1240*630 | 6100*1240*630 | |

| Block Size(mm) | L*W*H | 2000*1200*600 | 3000*1200*600 | 4000*1200*600 | 6000*1200*600 | |

| Capacity | Piece/hr | 7~20 | 7~20 | 7~20 | 3~17 | |

| Steam | Inlet | mm | 100 | 150 | 200 | 250 |

| Consumption | kg/cycle | 15-28 | 25-35 | 35-45 | 50-70 | |

| Pressure | Mpa | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | |

| Compressured Air | Inlet | mm | 40 | 40 | 40 | 50 |

| Consumption | m3/cycle | 1~1.5 | 1.5~1.8 | 1.8~2 | 2~2.3 | |

| Pressure | MPa | 0.6 | 0.6 | 0.6 | 0.6 | |

| Drainage | Venting | mm | 100 | 150 | 200 | 200 |

| Blower Aeration | mm | 100 | 125 | 150 | 200 | |

| Condensate | mm | 100 | 150 | 150 | 150 | |

| Hydraulic | Cylinder | Unit*dia. | 2*100 | 2*125 | 3*125 | 4*125 |

| Power | Kw | 3 | 3.75 | 4 | 5.5 | |

| Electrical Power | Kw | 11 | 15 | 22.5 | 24 | |

| Machine Size(mm) | L*W*H | 6250*3640*2900 | 7250*3640*2900 | 8250*3640*2900 | 10250*3640*2900 | |

| Machine Weight | Kg | 4500 | 6500 | 8800 | 10500 | |

Application

Steel tile

1. High quality

The foam machine line main parts are imported from famous factory in the world. Such as Siemens ; Delixi ;OMRON and etc.

2. Competitive price

Our eps block molding machine with competitive price because of the advance technology. So we are the best partner for you to choose !

3. Innovation

Our team developed the new solutions for different customers of different requirements.

4.CE

Lonkgou Shunda Machinery Equipment Co.,Ltd was established by one professional team with more than 30 years experience on EPS machine and EPS assistant equipment. we have our own factories and partners to cooperate together. Our customers has been extended all over the world, the company is developing and growing up rapidly.

1. Q: Are you a factory or trading company?

A: We are a factory.

2. Q: What certificate do you have?

A: We have ISO and CE certificate.

3. Q: How does your factory do regarding quality control?

A: We have a special QC department in charge of products’ quality.

4. Q: How long is the warranty period?

A: All of our products have one year warranty.

5. Q: What’s the main market of your company?

A: We have customers all over the world.

6. Q: How much production capacity of your company one year?

A: This depends on your needs.

7. Q: Where is your factory located? How can we visit there?

A: Our factory is located in Xufu Town, Longkou City, Shandong, China,We offer transportation service