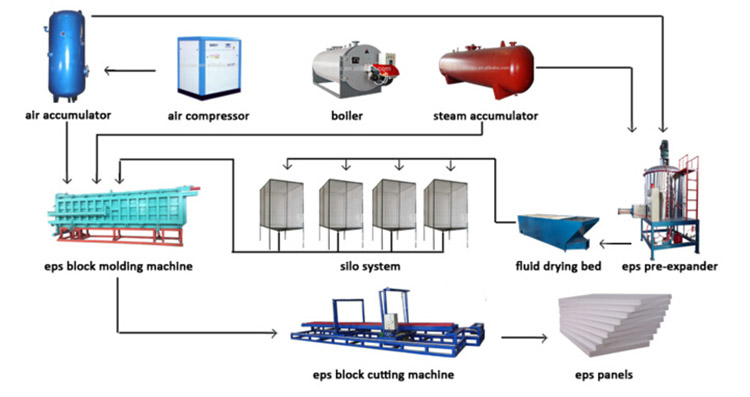

We supply complete eps foam production line and turnkey project. We can upgrade the machines according to customers’ requirements. Our company floor area 18000 square meters, has four big modern workshops.

Ⅰ.MAIN FEATURES:

1. This EPS foam block moulding machine adopts PLC programmable controller and touch human-machine interface control, automatic feeding, automatic control feeding process, has formed a complete guarantee automatic cycle of production equipment.

2. This EPS machine use high quality square tube and welded steel and other groups, each template through heat treatment and after assembly of small deformation, strength and durability

3. This EPS machine uses a unique heat penetration of advanced foreign EPS moulding process, penetrating ability, good adhesion, good product quality, significant energy saving features.

4. This machine uses advanced processing technology and piping layout, also refer to advantages of foreign board machine design unique structure, greatly improving production efficiency, also makes foam sheet production in the country reached a leading equipment position, is the ideal and efficient production equipment.

5. This machine uses the control instruments, electrical, pneumatic components, valves and other supporting both domestic and foreign high quality brand name products, the equipment into being regular, flat shape, reliable quality.

6. This machine uses hydraulic station centralized control, hydraulic single door, hydraulic and automatic ejection release the tight bodies, thus ensure the smooth operation of the machine, and reliable performance.

7. The machine features a highly efficient vacuum system and condensing units, penetrating ability, cooling speed, low moisture content, etc.

Ⅱ.Technical parameters:

Block polystyrene machine processors are facing two critical dilemmas which are high quality and effective energy saving. We can offer our customer the optimal & economical efficiency. Our new series block moulding machine can guarantee our customer the minimum investment cost at fastest return. Our customer can have the highest competitiveness in the market, thanks to our innovative design which is specially in short cycle time, good fusion and even density distribution.

| Description | Unit | PSB-2000 | PSB-3000 | PSB-4000 | PSB-6000 | |

| Mould Cavity Size(mm) | L*W*H | 2040*1240*630 | 3060*1240*630 | 4080*1240*630 | 6100*1240*630 | |

| Block Size(mm) | L*W*H | 2000*1200*600 | 3000*1200*600 | 4000*1200*600 | 6000*1200*600 | |

| Capacity | Piece/hr | 7~20 | 7~20 | 7~20 | 3~17 | |

| Steam | Inlet | mm | 100 | 150 | 200 | 250 |

| Consumption | kg/cycle | 15-28 | 25-35 | 35-45 | 50-70 | |

| Pressure | Mpa | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | 0.3~0.6 | |

| Compressured Air | Inlet | mm | 40 | 40 | 40 | 50 |

| Consumption | m3/cycle | 1~1.5 | 1.5~1.8 | 1.8~2 | 2~2.3 | |

| Pressure | MPa | 0.6 | 0.6 | 0.6 | 0.6 | |

| Drainage | Venting | mm | 100 | 150 | 200 | 200 |

| Blower Aeration | mm | 100 | 125 | 150 | 200 | |

| Condensate | mm | 100 | 150 | 150 | 150 | |

| Hydraulic | Cylinder | Unit*dia. | 2*100 | 2*125 | 3*125 | 4*125 |

| Power | Kw | 3 | 3.75 | 4 | 5.5 | |

| Electrical Power | Kw | 11 | 15 | 22.5 | 24 | |

| Machine Size(mm) | L*W*H | 6250*3640*2900 | 7250*3640*2900 | 8250*3640*2900 | 10250*3640*2900 | |

| Machine Weight | Kg | 4500 | 6500 | 8800 | 10500 | |

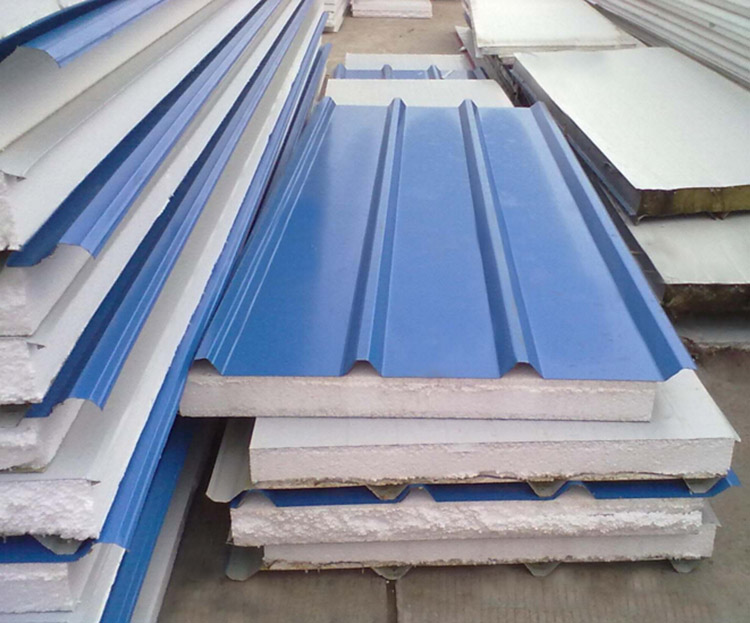

Application

Steel tile

1. High quality

The foam machine line main parts are imported from famous factory in the world. Such as Siemens ; Delixi ;OMRON and etc.

2. Competitive price

Our eps block molding machine with competitive price because of the advance technology. So we are the best partner for you to choose !

3. Innovation

Our team developed the new solutions for different customers of different requirements.

4.CE

Lonkgou Shunda Machinery Equipment Co.,Ltd was established by one professional team with more than 30 years experience on EPS machine and EPS assistant equipment. we have our own factories and partners to cooperate together. Our customers has been extended all over the world, the company is developing and growing up rapidly.

1. Q: Are you a factory or trading company?

A: We are a factory.

2. Q: What certificate do you have?

A: We have ISO and CE certificate.

3. Q: How does your factory do regarding quality control?

A: We have a special QC department in charge of products’ quality.

4. Q: How long is the warranty period?

A: All of our products have one year warranty.

5. Q: What’s the main market of your company?

A: We have customers all over the world.

6. Q: How much production capacity of your company one year?

A: This depends on your needs.

7. Q: Where is your factory located? How can we visit there?

A: Our factory is located in Xufu Town, Longkou City, Shandong, China,We offer transportation service